TV COF Bonding machine for Lcd Led Tv Screen panel Repair MT-B100

Overview

COF Bonding machine is used in a variety of FPC, COF,TAB and LCD Panel and PCB combination bonding, is reflected in a variety of sizes LCD vertical, horizontal, vertical band,horizontal belt,black belt, black, colored thread, ribbon , multi-line, black, black and white, vertical half display,horizontal half breakdown maintenance.

MT-B100 Specification for Download

Specification

Single Head Bonding Machine | |

Machine Name | COMPUTLER LAPTOP TV LCD PANEL REPAIR COF BONDING MACHINE; PULSE HEAT HOT PRESS MACHINE; DOUBLE HEAD BONDING MACHINE |

MODEL Number | MT-B100 |

Latest version | In 2015 |

Popular Country | TURKEY; BRAZIL; UK; |

Function | Ic tab cof flex cable replacement; pcb replacement; |

Application | Lcd screen panel display repair and refurbishment |

Usage | LCD vertical/horizontal lines, vertical/horizontal belt, |

Features | PULSE HEAT HOT PRESS, DOUBLE BONDING HEADS, DOUBLE PNEUMATIC DEVICES,DOUBLE TEMPERATURE CONTROLS |

Applicable LCD Panel Size | 13 inches to 100 inches Led Lcd Screen panel; Led Lcd TV screen panel. |

Applicable LCD panel thickness | 0.3MM-1.1MM [Single glass] |

Panel type | TFT |

Bonding IC number | One/PANEL |

Bonding head size | Highly recommended 68*1.2 or 68*1.4 |

Per customer’s requirement. CUSTOMIZED PER LAPTOP PCB SIZES | |

Equipment process time | TFT,3.8S/chip |

Bonding accuracy | ±1.5µm (support 4K) |

POSITION ACCURACY | ±0.5μm |

work environment | Clean, dust-free, clean room |

Working Air pressure | 0.1~0.7Mpa Dry air source |

Power supply | AC 220V±10%,50HZ,3500W |

Pneumatic device | Imported world famous brand AirTAC Original precision cylinder |

Pressure system | Pressure system parallel bar structure eliminates the weight of the indenter, pressure minimum accuracy can up to 0.1 KG, pressure components are using SMC precision components. |

Heating method | Pulse (rapid heating/cooling and auxiliary cooling) |

Temperature Control System | Brand:Omron |

Adjustable temperature rise curve with high precision PID auto-tuning | |

The peak temperature : within +/-1degrees Celsius | |

Room temperature time to 180 degrees the response time within 2-3 seconds | |

Hot pressing head | Material: Titanium alloy |

Metal properties:SUS440C | |

Origin: United States | |

Plane precision (hot pressing surface) :0.001mm | |

Plane thickness 0.5 (keep 3 times grinding) | |

Thermocouple Type | K type Original US OMEGA wire |

Industrial control unit / program | Panasonic PLC FX-C14T |

Panasonic Image Processing System | |

Touch unit | Display control Samkoon dual-core touch screen |

Image unit | COF counterpoint: Down counterpoint |

(Optical Path: Lens> Quartz> ITO Electrode> COF) | |

PCB alignment: with Front PCB Camera for PCB bonding | |

Number of lens: 2 | |

Microscope: 200-300 continuous zoom | |

COF Display: 19-inch HD | |

COF trimming unit | Origin: China |

Rail type: U-rail | |

Accuracy:0.01 | |

Adjustable direction: X/Y/R | |

R stroke: coarse adjustment 360 degrees, fine adjustment +/- 5 degrees | |

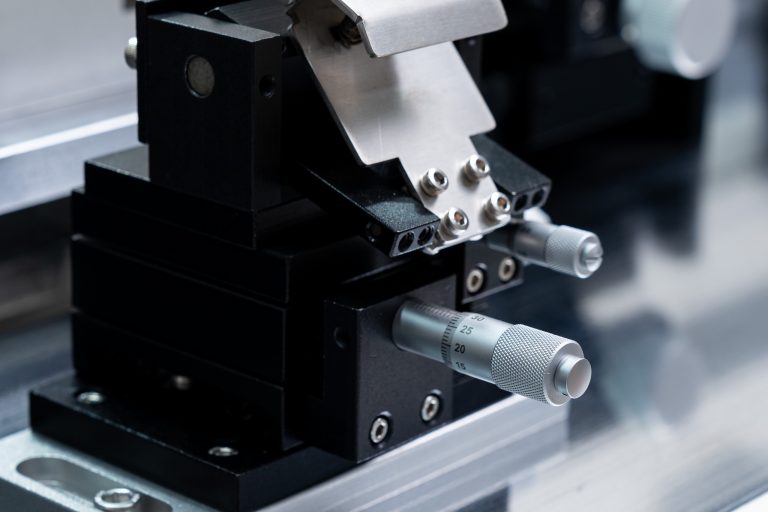

COF fixture | COF mechanical clamping type ,Z-direction tilt radius micrometer fine-tuning |

Lens spinner unit | Control mode: X / Y / Z micrometer control |

Focus Adjustment: Manually adjust the focus | |

Silicone / Teflon | Manual switching position |

LCD stage (platform) | Manual slide movement, self-contained vacuum adsorption device |

Bonding head alignment | The cylinder can be set to stop in any position in the upper and lower directions |

Control method | Touch screen + button operation |

Parameter setting | Can store multiple sets of hot pressing parameters as needed |

Rated voltage | AC 180-220V |

Peak power | 400-1100W (can support 68X1.2X10 wide bonding head) |

Maximum power | 1100W |

Actual power | 580W |

Body size | 1800X1260x1550mm(L*W*H) |

1160*850*1450mm(L*W*H) Without Platform size | |

Net weight of equipment | 380KG |

GLASS TABLE SIZE | Glass size: 1800*800*12MM |

Number of packages | 2 |

Equipment packaging | Wooden boxes, non-logs |

EXPORTED STANDARDS | |

Features

GOOD COMMENT AND FEEDBACK FROM BUYERS

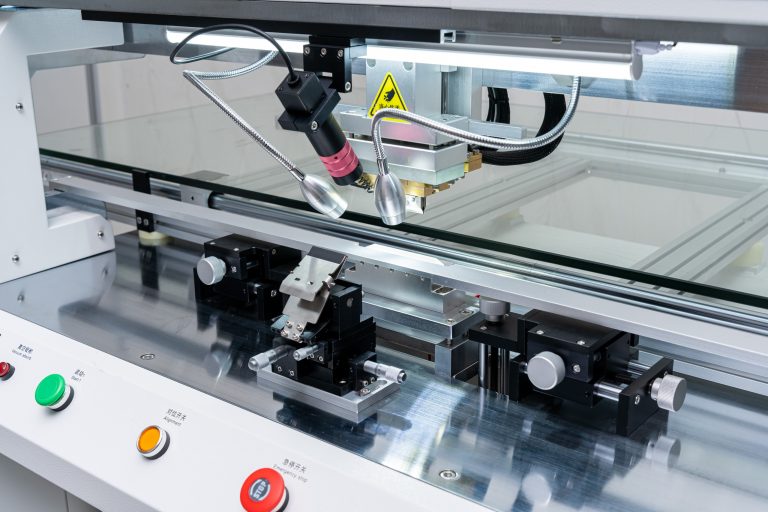

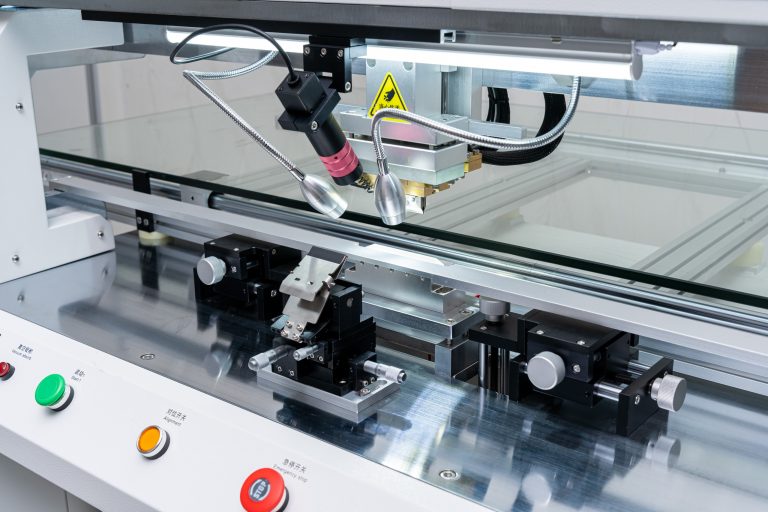

2 HIGH RESOLUTION CCD CAMERAS for COF ALIGNMENT

DOUBLE 19 INCHES MONITOR 1 FRONT PCB CAMERA

FULL SET ACCESSORIES PROVIDED 13-100 INCH LCD SCREEN PANEL REPAIR

1 YEAR WARRANTY EASY OPERATION AND MAINTENANCE

VARIOUS WAYS OF TRAINING

EMERGENCY STOP

LIFE-TIME MAINTENANCE

HUMANIZED DESIGN AND USER FRIENDLY

PANEL VACUUM ABSORPTION DESIGN

PRE-BONDING HOT PRESS DESIGN

Details

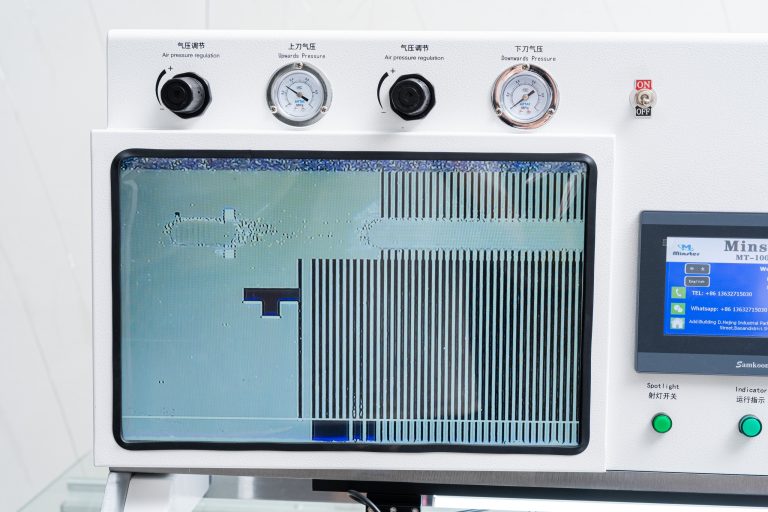

Dual 19 Inches High Resolution Monitors

with Large Size and high resolution Monitors, it is easy to see the cof lines and helpful to do alignment while bonding.

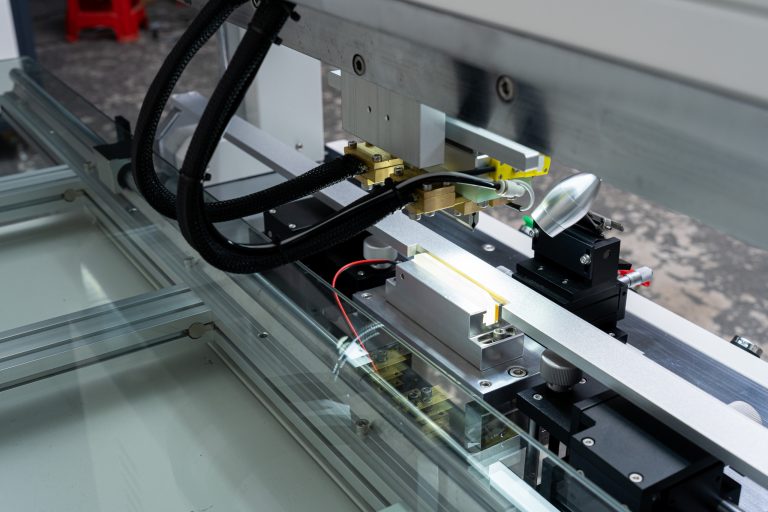

Unique bonding head design

Bonding Temperature is even and bonding head not movable while bonding

high Resolution Front PCB Camera

68*1.4 Pulse Heat Hot Press Bonding Machine can repair all COFs

Accurate and Precise COF Alignment System

Vacuum Absorption System to avoid panel moving during Bonding

Emergency Stop Design to protect your machine

Packing & Delivery

※ Safe Exported Standard Wooden Boxes

※ Due to Heavy weight and Large size of the machine, we recommend Shipping By Sea.